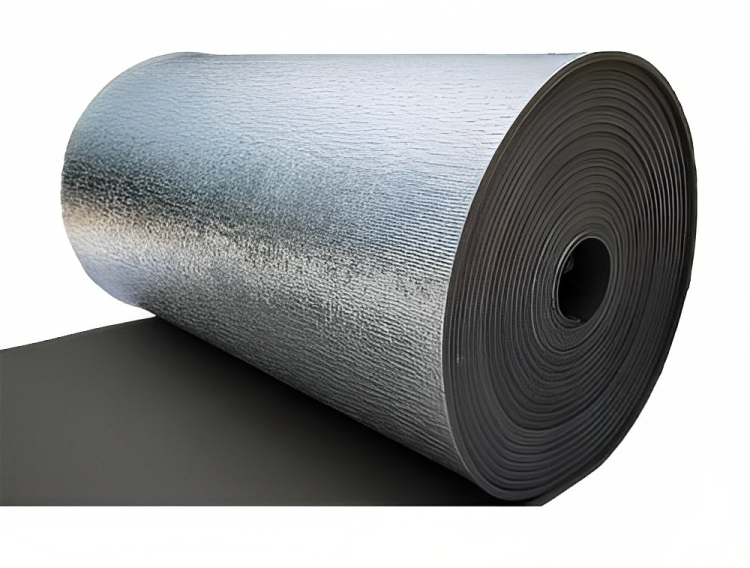

XLPE Sheet (One Side Alu. Foil)

Cross-Linked Polyethylene (XLPE) Sheets in their plain form stand as a testament to modern insulation technology. These sheets offer a unique combination of electrical and thermal insulation, making them a versatile and valuable solution for a wide range of applications. Engineered with precision, XLPE Sheets provide a reliable barrier that ensures the safety and efficiency of various systems and components.

| Parameter | Value |

| Material (ASTM C 1427) | Chemically Cross Linked Closed Cell Polyethylene Foam Insulation |

| Thickness | 3mm, 6mm, 9mm, 13mm, 15mm, 19mm, 25mm, 30mm, 35mm, 40mm, 50mm |

| Color | Grey |

| Width | 1.2 M |

| Temperature Range | – 40° C to +115° C |

| Nominal Density | 30 + 3 Kg/m3 |

| Thermal Conductivity | Mean Temperature (C) W/m °K Kcal/hr m (C) 0 0.0318 0.0273 23 0.0329 0.0283 46 0.0382 0.0328 |

| Parameter | Value |

| Water Vapour Resistance Factor (u) (MEW) – (DIN 52615) | Moisture Resistance Factor (u) > 9000 (for plain foam) > 14000 (for Al foil faced foam) |

| Reaction to Fire | Self Extinguishing, Non-toxic Ozone: Very Good |

| Dimensional Stability: BS 4370 Part 1 | Change in dimensions at – 20 °C for 4 hrs <<0.5% and at 110 °C for 4 hrs :< 0.5% |

| Limiting Oxygen Index: ASTM D 2863 | 24% |

| Compression Strength @ 25%: ASTM D 3575 | 0.44 Kgf/cm2 |

| Resistance to Chemical: ASTM C 543 | No characteristic change observed |

| Tensile Strength @ 50 mm / min: ASTM D 3575 | 2,51 Kgf/cm2 |

| Parameter | Value |

| Elongation at Break: ASTM D 3575 | 133.20% |

| Fungal Resistance: ASTM G21 | No growth observed |

| Volume %-age of closed cells: ASTM D 6226 Part 2 | > 90% |

| Sound Transmission Class for 9 mm foam with 12 mm Gypsum board: ASTM E 413 / ISO 140 | 40 dB |

| Water Absorption: ASTM C 209 / ASTM 1763 | <0.2% |

| Water Vapour Permeance: ASTM E96 | 0.15 ng/pas.m |

| Health & Safety Aspects | CFC / HCFC Free; Dust and Fibre free, VOC / SVOC Free |

| Emission of Volatile Organic Compound (VOC) | Negligible |

Applications

- Duct Insulation: These sheets are commonly used in HVAC duct systems to provide thermal insulation and prevent heat loss or gain. The aluminum foil layer enhances energy efficiency by reflecting heat.

- Pipe Insulation: XLPE sheets with aluminum foil are utilized to insulate pipes, preventing condensation and maintaining temperature stability in plumbing and industrial pipelines.

- Roof and Wall Insulation: These sheets are employed as part of insulation systems for roofs and walls, enhancing energy efficiency and contributing to comfortable indoor environments.

- Electrical Enclosures: The aluminum foil's electromagnetic shielding properties make these sheets suitable for lining electrical enclosures, protecting sensitive electronic components from interference.

- Automotive Insulation: XLPE sheets with aluminum foil find use in the automotive industry for insulation under vehicle hoods, in engine compartments, and in the cabin to manage heat and noise.

- Electronic Devices: The electromagnetic shielding properties make these sheets valuable for insulating and protecting electronic devices and equipment from electromagnetic interference.

Advantages

- Enhanced Thermal Insulation: The addition of aluminum foil to one side of the XLPE sheet boosts its thermal insulation effectiveness. The reflective nature of the foil helps to reflect radiant heat, contributing to better temperature control and energy efficiency.

- Moisture Barrier: The aluminum foil acts as a moisture barrier, preventing the ingress of water and moisture from the external environment. This is particularly advantageous in applications where moisture resistance is essential, such as HVAC systems or outdoor installations.

- Electromagnetic Shielding: Aluminum foil has excellent electromagnetic shielding properties. When used in XLPE sheets, it provides protection against electromagnetic interference (EMI) and radiofrequency interference (RFI), making these sheets suitable for applications where electromagnetic compatibility is crucial.

- Durability and Weather Resistance: The combination of XLPE and aluminum foil creates a durable and weather-resistant material. It can withstand exposure to UV radiation, temperature fluctuations, and environmental elements, ensuring long-lasting performance.

- Ease of Installation: The XLPE sheet with one side aluminum foil retains the flexibility and ease of installation characteristic of XLPE materials. It can be easily cut, shaped, and installed on various surfaces, reducing installation time and effort.

- Corrosion Protection: The aluminum foil provides an additional layer of protection against corrosion, which is especially beneficial in environments where metal components are prone to rust or degradation.

- Aesthetic Appeal: The aluminum foil side of the sheet can have an aesthetic appeal, and it can be used for both functional and decorative purposes, particularly in applications where the sheet is visible.

Manufactures We Have