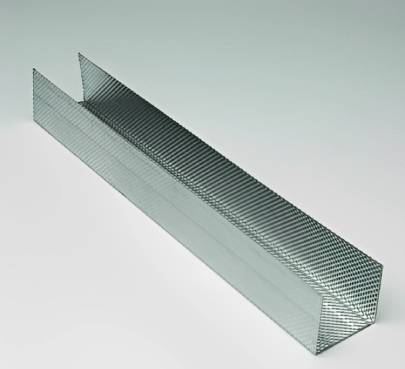

GI Angle

GI angle is an L-shaped piece of steel or iron that has been galvanized for added corrosion resistance. It features a right-angle bend with two legs of equal or unequal length, forming a 90-degree angle. This shape makes GI angles highly versatile for structural support and framing applications.

Properties

- Galvanized Finish: The zinc coating on GI angles provides corrosion resistance, protecting the underlying iron or steel from rust and deterioration.

- Strength: GI angles are known for their strength and load-bearing capacity, making them suitable for structural applications.

- Versatility: They are available in various sizes, lengths, and thicknesses to accommodate different project requirements.

- Ease of Fabrication: GI angles can be easily cut, welded, drilled, and machined to fit specific design and construction needs.

- Durable: The galvanized coating enhances the durability and lifespan of GI angles, especially in outdoor or corrosive environments.

Applications

- Building Construction: They are used for framing and supporting structures in buildings, including walls, ceilings, and roofs.

- Industrial Equipment: GI angles serve as components in the fabrication of machinery, conveyor systems, and equipment frames.

- Fencing and Gates: They are employed in fencing, gate frames, and guardrails, providing both structural support and a protective barrier.

- Electrical and Telecommunication Towers: GI angles are used in the construction of towers for electrical transmission lines and telecommunication equipment.

- Shelving and Racks: In warehousing and storage facilities, GI angles are used to create sturdy shelving and storage racks.

- Support Brackets: They provide support for various components, such as air conditioning units, signage, and lighting fixtures.

- Trusses and Framing: GI angles are essential components in roof trusses, wall framing, and structural frames for buildings and bridges.

Advantages

- Corrosion Resistance: The galvanized coating protects GI angles from rust and corrosion, making them suitable for outdoor and high-moisture environments.

- Strength and Durability: GI angles offer high strength and durability, ensuring long-lasting performance in structural applications.

- Versatility: They are adaptable to a wide range of applications, thanks to their customizable sizes and ease of fabrication.

- Cost-Effective: GI angles are a cost-effective choice for structural and framing purposes.

- Easy Maintenance: They require minimal maintenance, primarily consisting of periodic inspections for damage to the galvanized coating.