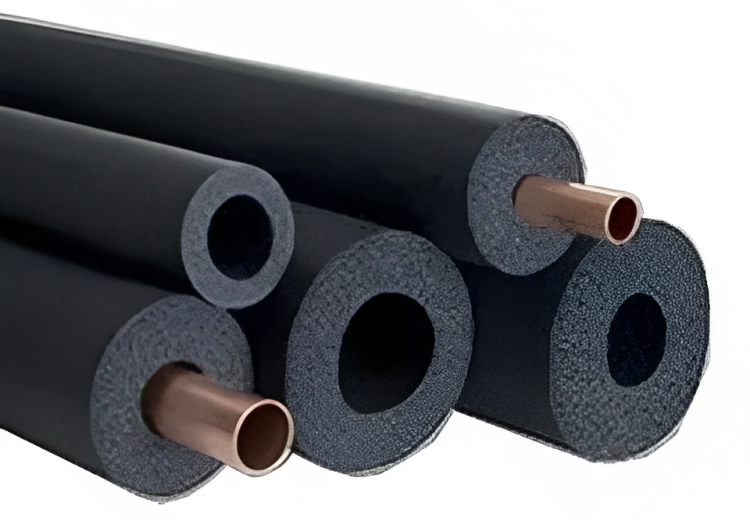

Nitrile Rubber Pipe Tubing (Plain)

Nitrile rubber pipe tubing, also known as NBR tubing, is a type of synthetic rubber tubing that is composed of nitrile butadiene rubber. It is known for its excellent oil resistance, flexibility, and durability. Nitrile rubber is created through the polymerization of acrylonitrile and butadiene, resulting in a material with high resistance to various fluids, chemicals, and environmental conditions.

Applications

- Industrial piping,

- HVAC systems,

- oil refineries.

- Automotive Industry: Nitrile rubber tubing is commonly used in the automotive sector for fuel lines, transmission fluid lines, and other applications where resistance to oil and fuel is crucial.

- Industrial Machinery: It is used in industrial machinery for hydraulic and pneumatic systems due to its resistance to hydraulic fluids and lubricating oils.

- Chemical Processing: NBR tubing is used in chemical processing industries for the transport of corrosive chemicals, acids, and alkaline solutions.

- Oil and Gas: In the oil and gas industry, NBR tubing is utilized for various applications, including the transfer of crude oil, refined petroleum products, and drilling fluids.

- Laboratory and Medical: Nitrile rubber tubing is used in laboratory equipment and medical devices for fluid handling due to its chemical resistance and biocompatibility.

- Food and Beverage: It is also used in the food and beverage industry for conveying non-fatty and non-oily liquids.

- Agriculture: NBR tubing finds use in agricultural equipment for irrigation systems and chemical application.

- Marine Applications: It is employed in marine environments for applications like fuel lines, bilge pump systems, and water circulation systems

Advantages

- Oil and Fuel Resistance: Nitrile rubber tubing exhibits exceptional resistance to oils, fuels, and petroleum-based fluids. This property makes it highly suitable for applications involving the transfer of liquids in industrial and automotive environments.

- Flexibility: NBR tubing is flexible and can be easily bent, twisted, and manipulated without losing its structural integrity. This flexibility makes it suitable for various routing and installation requirements.

- Durability: Nitrile rubber is known for its robustness and resistance to abrasion, tearing, and wear. This durability ensures that the tubing can withstand the rigors of industrial applications.

- Chemical Resistance: NBR tubing is resistant to a wide range of chemicals, including many acids, alkalis, and solvents. This makes it suitable for use in applications where exposure to harsh chemicals is a concern.

- Temperature Range: Nitrile rubber tubing can operate effectively within a broad temperature range, typically from around -40°C to 100°C (-40°F to 212°F), making it suitable for both high- and low-temperature environments.

- Low Permeability: NBR tubing has low gas permeability, meaning it is less likely to allow gases to pass through its walls. This property can be advantageous in applications involving gases or volatile substances.

- Cost-Effective: Nitrile rubber is relatively inexpensive to produce, making NBR tubing a cost-effective solution for various industrial and commercial applications.

Manufactures We Have