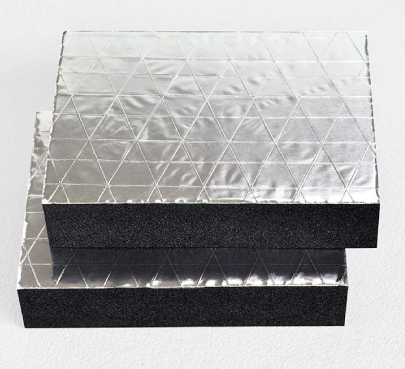

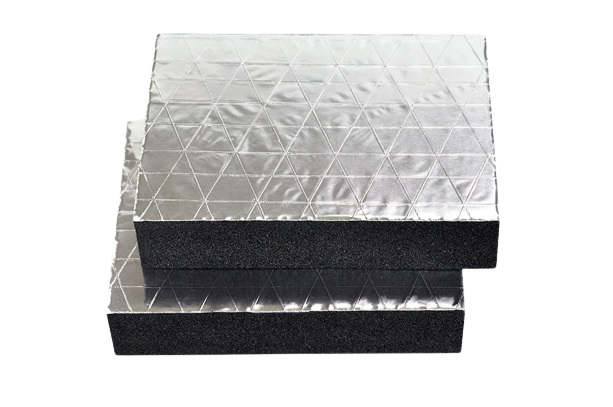

Nitrile Rubber Sheet (Alu. Foil)

Nitrile rubber sheets with aluminum foil, often referred to as Nitrile Rubber Sheet with Aluminum Foil Backing, combine the properties of nitrile rubber with the added benefit of an aluminum foil backing. This backing enhances the sheet’s performance and extends its applications to areas requiring heat reflection, moisture barrier, and added strength.

| Parameter | Value |

| Density (Kg/M³) | 40-60 |

| Thermal Conductivity | 0.038 (at ambient) |

| Thicknesses (mm) | 6, 9, 13, 19, 25, 32 |

| Temperature Range | -40°C to +105°C |

| Water Vapour Diffusion | >= 7000 |

| Corrosion Risk | Non Corrosive |

| Toxicity | Low carbon monoxide formation |

| Asbestos | No Asbestos |

| Fungus Growth | No growth observed |

| Closed Cell | 90% |

| Resistance to Oil & Grease | Very Good |

Applications

- Sealing and Gasketing: Nitrile rubber sheets are often used to create seals and gaskets in automotive engines, machinery, and equipment to prevent leakage of fluids.

- Vibration and Impact Isolation: Their flexibility and shock-absorbing properties make these sheets suitable for applications where vibration and impact need to be dampened.

- Industrial Protection: Nitrile rubber sheets are used for lining tanks, chutes, and other equipment in industrial settings to protect against abrasive materials, chemicals, and wear.

- Automotive Industry: They are used in various automotive components such as oil seals, fuel system components, and gaskets.

- Mining and Construction: Nitrile rubber sheets find application in mining equipment, construction machinery, and other heavy-duty industrial equipment.

Advantages

- Oil and Fuel Resistance: One of the primary advantages of nitrile rubber sheets is their exceptional resistance to oils, fuels, and lubricants. This property makes them well-suited for applications in automotive, industrial machinery, and fuel-handling systems.

- Chemical Resistance: Nitrile rubber sheets exhibit good resistance to a wide range of chemicals and solvents, making them suitable for use in environments where exposure to various chemicals is likely.

- Flexibility: These sheets maintain their flexibility over a wide temperature range, which allows them to be used in both high and low-temperature environments.

- Tear and Abrasion Resistance: Nitrile rubber sheets have relatively high tear and abrasion resistance, making them durable and capable of withstanding mechanical stress.

- Water Resistance: While nitrile rubber is not as inherently water-resistant as some other elastomers like neoprene, it still offers moderate water resistance and can be used in applications where water exposure is limited.

Manufactures We Have